Real-time load weight monitoring

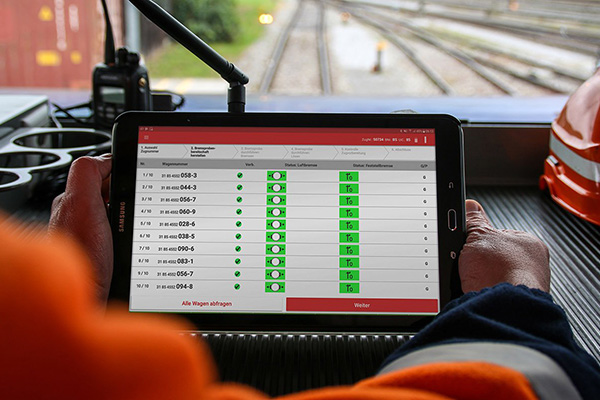

Faster and safer loading thanks to automatic load monitoring. The LoadMonitor system enables the loading process to be monitored directly on site and loading to be carried out quickly and correctly. During the loading process, signal lamps on the wagon indicate in real time when the maximum loading weight has been reached or the load is asymmetrically distributed. This ensures that the wagon is optimally and correctly loaded and that the maximum load capacity is used to its full potential. The loading process is completed more quickly and the person responsible for loading can be sure that overloading has been ruled out. The system not only increases efficiency, but also the safety of goods transport.

Advantages

- Lower costs thanks to the best possible utilization of loading capacity

- Prevention of overloading, as the maximum weight is no longer exceeded

- Time saving: faster loading & no more lengthy queuing at infrastructure checkpoints as the loading limit is adhered to

- Lower maintenance costs & higher mileage due to less stress on the wheelsets and bogie frame

- Optimized maintenance based on actual mileage and usage

- Control of weighing data provided by the customer

- Efficient process as time-consuming manual weighing is no longer necessary

- Less wheelset damage thanks to optimized brake adjustment in the train set

- Increased safety as individual components are no longer overloaded

- Real-time information on loading progress and shunting times for end customers and freight forwarders

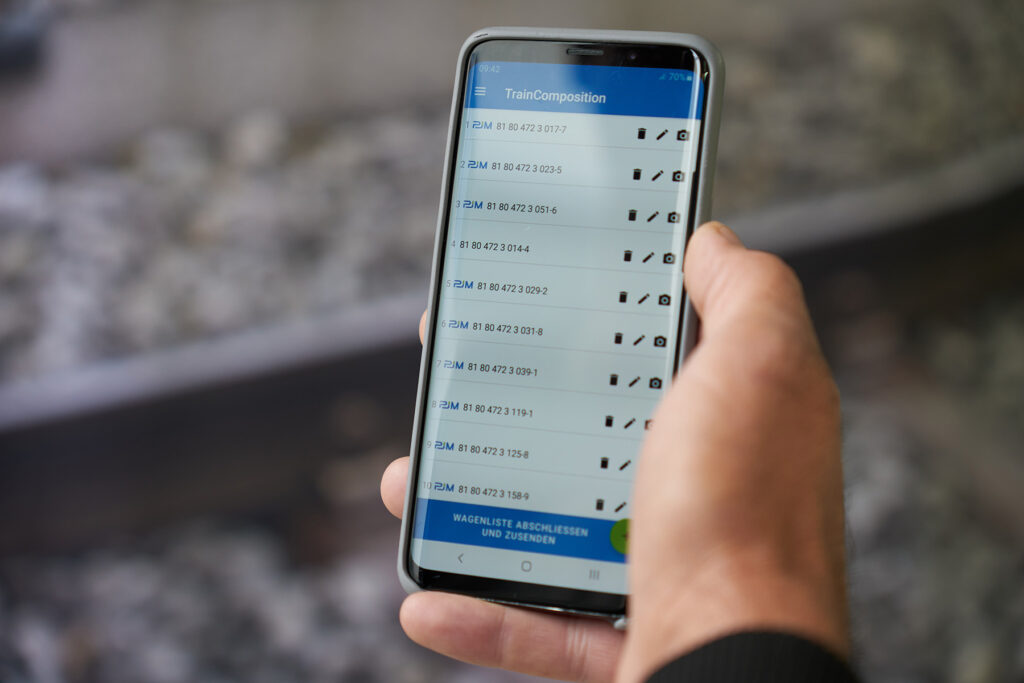

- Digital train lists including the actual individual and total weights

- Higher availability

The most important facts about load weight monitoring

- Recording of the total weight and optional bogie / wheel set /wheel disc load

- On-site display on the vehicle possible using signal lamps

- Geofence / route class-based parameterization of the maximum weight

- Real-time transmission in the web portal

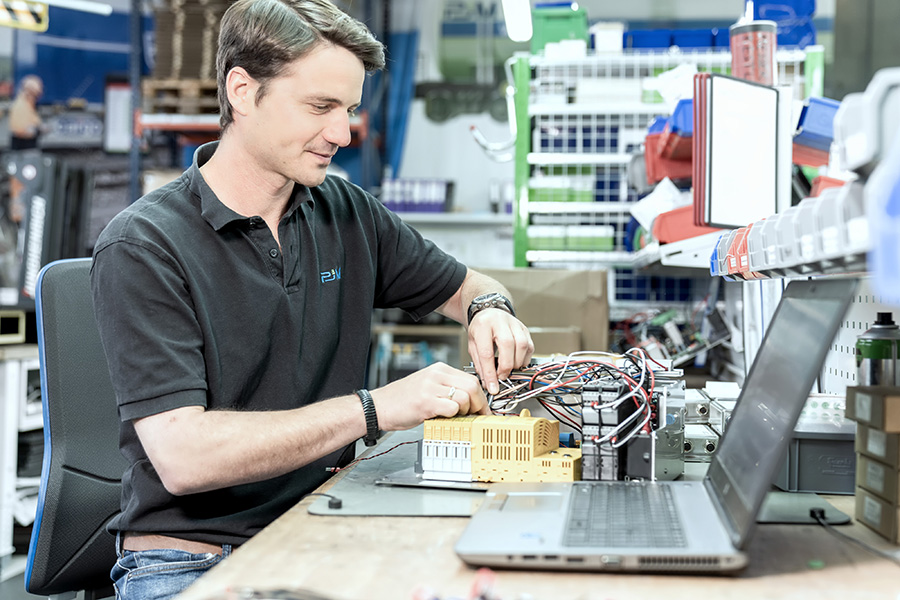

- Precise and wear-free strain gauge technology (strain gauges)

- Calibration and limit value change over the air (OTA)

Contact:

Felix Egger-Cimenti

egger-cimenti@pjm.co.at

+43 676 4048663

Do you have questions about our digital technology?

Simply fill in the form or contact Felix Egger-Cimenti directly.